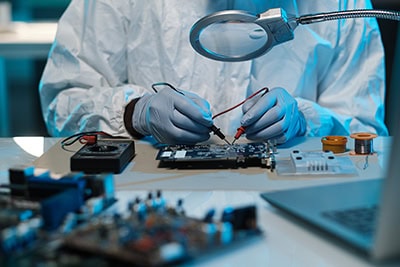

With years of expertise, Omega GTI’s Test Inspection Laboratory Services is your trusted partner for component authenticity verification. Our advanced in-house tools and counterfeit detection methods guarantee the integrity of your materials, ensuring seamless operations and peace of mind.

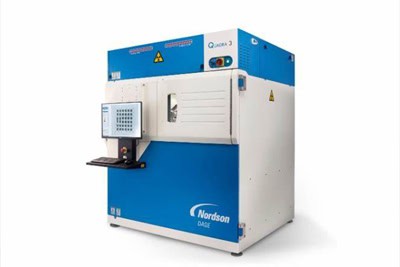

We specialize in Real-Time X-ray Inspection for electronic assemblies, PCB boards, and failure analysis. Here’s a look at the high-end equipment we use to screen your materials with precision.

A destructive test using the latest laser decapsulation technology that replaces traditional chemical etching processes. This provides fast and accurate solutions for IC de-capsulation and de-lidding, expose the insides from ceramic, KOVAR, gel, and mold compound capsulation, expose defective bonding wires, observe solder ball mid-position and lamination cracks, and more evidence of failure.

A destructive test to determine component leads/pads are free from oxidation and can still meet MIL-STD-883 and IPC-610 requirements.

Compromised moisture sensitive devices are subjected for baking to bring the components to a dry condition following OCM requirements and vacuum sealed with nitrogen purge system to flush out package moisture to protect and extend the life of moisture sensitive materials.

This ensures that components conforms with OCM datasheet and MIL-STD-883 from packaging up to the component level utilizing the most advanced digital microscope with 20X~2500X magnification.

Widely considered as a non-destructive test following MIL-STD-883 used to verify internal condition of the lead frame, die condition and wire bonds.

XRF is a non-destructive analytical technique used to determine the elemental composition of materials mainly for RoHS compliance.

© Copyright 2025. Omega GTI